“Zero Waste” is a concept taken to heart by Toyota’s Burnaston car plant, where even the residue from waste water treatment is being recycled, supplied as a raw material for use in cement production.

Toyota Manufacturing UK’s factory near Derby processes more than a quarter of a million cubic metres of waste water a year, filtering out metals and other contaminating materials so that it is clean enough to enter the sewer system. The material left behind, a filter “cake” rich in calcium, is shipped on to a third party business that recycles it in cement production for the construction industry.

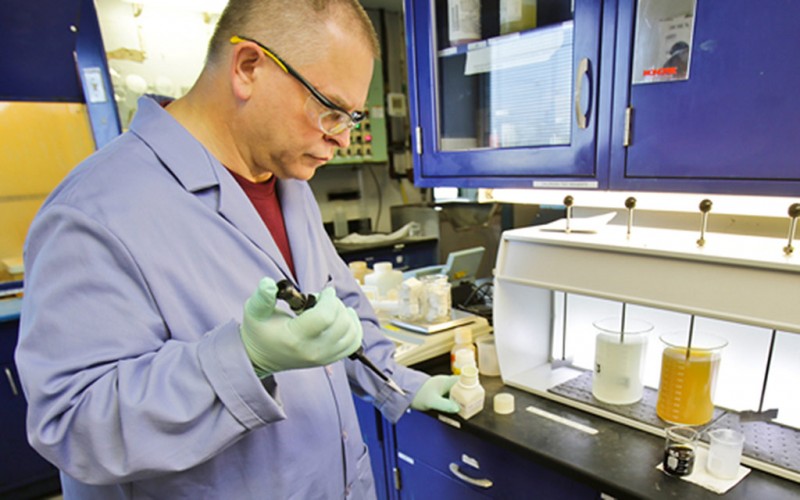

The recycling opportunity was made possible after TMUK adopted a non-hazardous liquid lime product for the treatment process. Replacing the dry lime powder used previously, this made the operation quicker, cleaner and cheaper and used less manpower. Currently up to 300 tonnes of the filter cake are produced by the plant each year.

Similar technology has been adopted by Toyota’s manufacturing facility in Indiana in the USA, where its introduction has eliminated one million pounds of waste water sludge a year. Like Burnaston, the Indiana operation sends no waste to landfill.

Burnaston, home to production of the Toyota Auris, Auris Touring Sports and Avensis, has a distinguished environmental record and enjoys the status of one of Toyota’s global eco-plants, pioneering best practice and innovation in the capturing of renewable energy, reducing the usage of natural resources and minimising waste.

Source; Toyota